Open Standard Modules (OSM): Fueling the Future of Wireless Embedded Systems

Embedded engineers today face a dilemma: how to add more computing and connectivity into ever-smaller devices without reinventing the wheel each time. Open Standard Modules (OSM) have emerged as a compelling answer. OSM is a new open specification for tiny, solderable computer modules that pack processors, memory, and wireless connectivity onto a standardized footprint. About the size of a postage stamp in its smallest form, an OSM module can bring full computer functionality (and internet connectivity) to almost any object. In this article, we’ll explore what OSM is, why it’s poised to transform wireless embedded design, and how it leverages the power of open standards – much like Wi-Fi and Bluetooth did for wireless communication – to accelerate innovation across industries.

What Are Open Standard Modules (OSM)?

Open Standard Modules are a new industry standard for ultra-compact, solderable computer-on-modules designed for embedded and IoT applications. Launched by the Standardization Group for Embedded Technologies (SGET) in late 2020, the OSM specification defines a family of small form-factor modules that include processor, memory, power management, and connectivity on a tiny board. The core idea behind OSM is to provide a future-proof, versatile module standard that addresses the growing need for cost-effective, space-saving, and feature-rich computing solutions. In essence, an OSM is like a miniaturized System-on-Module (SoM) that can be machine-assembled (soldered directly onto a carrier board) without bulky connectors, simplifying integration and improving reliability. Key characteristics of the OSM approach include being fully machine-solderable (no connectors needed), offering multiple standardized module sizes, providing a consistent set of pre-defined hardware interfaces, and embracing an open-source hardware/software ecosystem. Together, these qualities allow OSM modules to be easily automated in production and integrated into designs while remaining scalable and vendor-neutral.

OSM Form Factors and Specifications

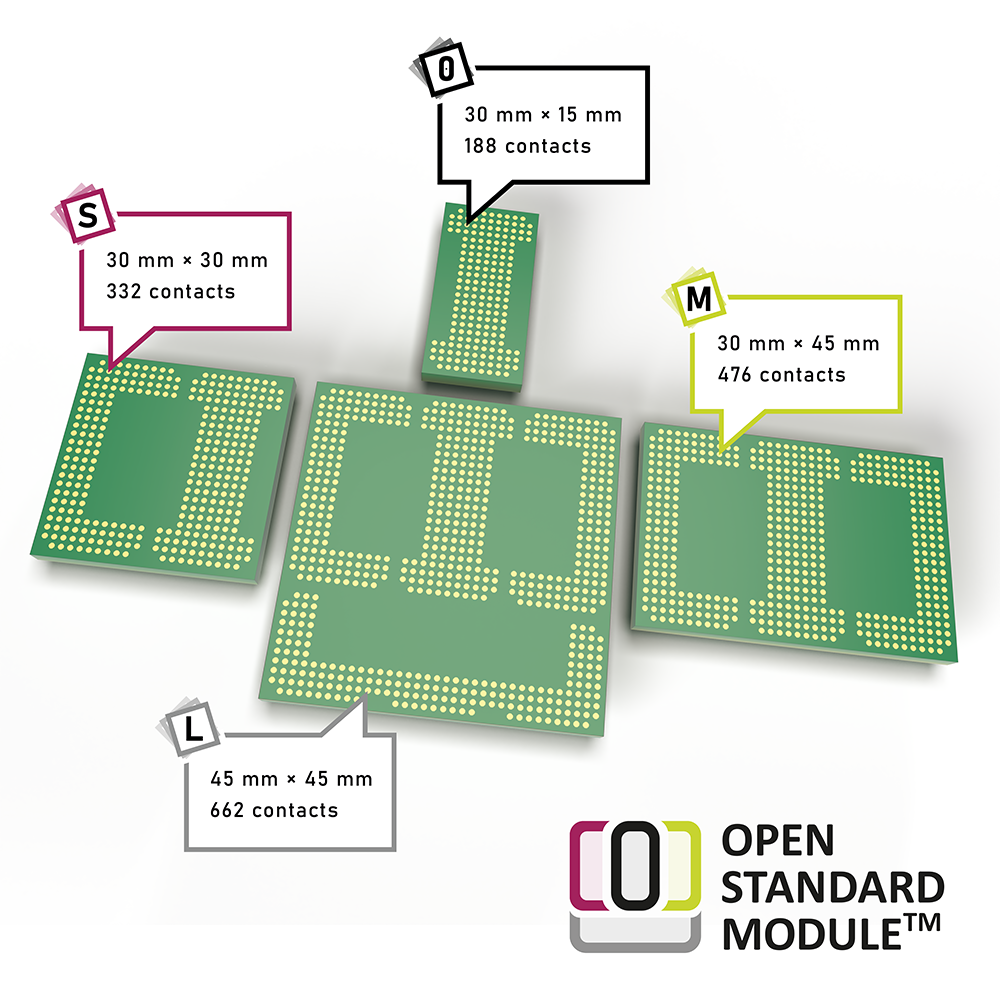

One of the standout features of OSM is the range of module sizes defined, which cater to different levels of functionality. Each size variation shares the same connectorless BGA concept and pin naming scheme, but offers increasing I/O capabilities as you go larger. OSM defines four module footprints: Size-0 (30×15 mm, 188 pins), Size-S (30×30 mm, 332 pins), Size-M (30×45 mm, 476 pins), and Size-L (45×45 mm, 662 pins). Larger modules in this family include more interface capabilities – for example, Size-S and above add display and camera interfaces and at least one PCIe lane, Size-M supports additional display outputs (e.g. eDP) and more PCIe, and Size-L brings the full set of high-speed interfaces (including LVDS display and up to 10 PCIe lanes).

Each OSM size is designed to be a superset of the smaller sizes in terms of functionality, enabling pin-compatible forward and backward migration across the range. In practice, that means a carrier board can often accommodate multiple OSM sizes for scalability. You might prototype with a Size-S module and later upgrade to a Size-M or L for more performance, reusing the same board design – a powerful feature for iterative development. The OSM specification even accounts for module height variations: it defines options for single-sided (“Flat”) or double-sided (“Extended”) component mounting. This allows module vendors to include additional chips (like larger RAM or flash) on the underside of the PCB if needed, offering higher-performance variants without changing the footprint.

The full OSM specification is available from SGET on their website.

OSM vs. Traditional Module Standards

Experienced engineers may recall earlier computer-on-module standards like COM Express, SMARC, or Qseven. OSM is not a direct replacement for those – rather, it complements them by targeting a smaller form factor and a solder-down design. Traditional COM modules often use board-to-board connectors and measure in the tens of square centimeters. For example, a SMARC module is about 82 × 50 mm with a 314-pin connector, and even a “micro” Qseven is 40 × 70 mm with a 230-pin connector. In contrast, OSM’s largest variant (Size-L) is just 45 × 45 mm yet carries 662 contacts in a BGA package – packing more interfaces into a much smaller footprint. This level of miniaturization is groundbreaking, achieved without losing functionality, and is a key advantage of the OSM approach.

To illustrate the differences, the table below contrasts the largest OSM module with two earlier industry standards:

| Module Standard | Dimensions (mm) | Connector / Pins | Notable Characteristics |

|---|---|---|---|

| OSM Size-L (SGET, 2020) | 45 × 45 | Soldered BGA / 662 contacts | Latest solder-down module; also defined in smaller sizes down to 30×15 mm. High I/O count (multiple displays, up to 10 PCIe lanes) in a compact footprint. Open-source hardware/software support. |

| Micro Qseven (SGET, ~2012) | 40 × 70 | Card-edge connector / 230 pins | Earlier pluggable module standard for mobile/IoT. Slim profile, limited pin count. Typically used for low-power CPUs with basic graphics, audio, and network features. |

| SMARC 2.0 (SGET, 2013) | 82 × 50 | Board-to-board connector / 314 pins | Pluggable module for sub-6W systems. Larger credit-card form factor. Supports multimedia (graphics, audio) and multiple interfaces, but uses a board connector and is physically bigger. |

Another major difference is OSM’s soldered BGA design versus the removable modules of older standards. By eliminating the connector, OSM modules become a permanent part of the device PCB – which greatly increases robustness (no chance of connectors loosening) and can lower cost and assembly complexity. This makes OSM well-suited for industrial IoT, wearables, and other applications where compactness and durability are critical. The trade-off is that OSM modules aren’t meant to be user-swappable, but for many embedded products that’s an acceptable or even desirable situation. Lastly, OSM’s philosophy is very open: the spec is published by SGET for any vendor to implement, and reference designs and software are often provided openly. This contrasts with some legacy module ecosystems that, while standardized, didn’t emphasize open-source support. With OSM, as we’ll discuss, the hardware standard is accompanied by open-source software resources, encouraging a community-driven ecosystem.

Key Features and Advantages of OSM

Now that we have an overview of what Open Standard Modules are, let’s summarize why an engineer or product developer might choose OSM for their next design. Below are some of the standout features and advantages that OSM brings to the table:

- Compact Size with High Integration: OSM modules pack a full computing system (CPU, RAM, storage, power management, etc.) into an incredibly small package. Even the “Large” 45×45 mm module can outdo larger COMs in terms of interface count, thanks to the dense BGA layout. This makes it feasible to put substantial processing power into devices that have tight space constraints, without sacrificing needed I/Os.

- Rugged, Soldered Design: The solder-on nature of OSM means no board-to-board connectors. In harsh environments – think heavy machinery, automotive, or outdoor sensors – vibration and shock can wreak havoc on connectors. OSM, being soldered directly, is much more robust against such conditions. The BGA attachment also improves signal integrity and can simplify design for high-speed signals (shorter interconnects).

- Scalability and Upgrade Path: With four module sizes and multiple CPU architecture options (ranging from microcontroller-level to 64-bit application processors), OSM offers a clear scalability path. Developers can prototype with a smaller OSM and later upgrade to a more powerful module without changing the carrier board, since the pin assignments stay consistent across all sizes.

- Wireless and Network Ready: Modern IoT devices require connectivity, and OSM has been designed with that in mind. Each module includes a dedicated “communication interface area” of pins reserved for wireless connectivity signals or fieldbus connections. Many OSM modules come with built-in wireless radios or connectivity options – for example, some (such as Ezurio’s CarbonAM62 and CarbonAM67 SOMs) have onboard Wi-Fi and Bluetooth modules, integrated to cater to wireless applications. Even when wireless chips aren’t included on the module, the pinout makes it straightforward to attach external radios (like cellular modems or Wi-Fi chipsets) via standard interfaces (such as PCIe, USB, SDIO, or UART). In short, OSM is IoT-ready out of the box.

Wireless Connectivity in Open Standard Modules

Wireless communication is a critical aspect of modern embedded systems, and OSM was built with that reality in mind. Each OSM module reserves 18 specific BGA contacts as a communication interface area for wireless connections, simplifying the hookup of antennas or external RF modules. Many OSM modules even include built-in wireless radios (like Wi-Fi/Bluetooth or sub-1GHz), making them ready for IoT applications out-of-the-box. Below are some of the major open wireless standards commonly used in OSM-based designs, and how they fit in:

- Wi-Fi (IEEE 802.11): Wi-Fi is a ubiquitous WLAN standard for high-speed wireless networking. OSM designs can integrate Wi-Fi easily (e.g., via PCIe or SDIO interfaces to a Wi-Fi module), using the module’s antenna pins for seamless connectivity. As an open IEEE standard, Wi-Fi ensures multi-vendor interoperability, aligning with OSM’s ecosystem approach.

- Bluetooth (BLE): Bluetooth Low Energy enables short-range, low-power wireless links for peripherals and wearable devices. Many OSM-based systems include Bluetooth (often via combo Wi-Fi/Bluetooth chipsets), allowing devices like sensors or smart gadgets to connect with phones or nearby hubs. Being an open standard managed by the Bluetooth SIG, it guarantees compatibility across a broad range of devices.

- Cellular & LPWAN: For long-range connectivity, OSM devices can leverage cellular networks (4G/5G) or low-power wide-area networks like NB-IoT and LoRaWAN. These typically use external modem modules attached via OSM’s standard interfaces (USB, PCIe, etc.), enabling an OSM-based system to send data over telecom or IoT networks. These wireless protocols are defined by open industry standards (3GPP, LoRa Alliance), ensuring that OSM implementations can interface reliably with existing infrastructure.

Thanks to its standardized approach, an OSM module can readily incorporate whatever wireless technology a project demands – whether it’s high-throughput Wi-Fi for data-intensive applications, Bluetooth for device pairing and mesh sensor networks, or cellular for remote connectivity. The end result is that designers have a connectivity-ready module: much of the RF integration work is already handled or simplified by the OSM spec, accelerating development of connected devices.

Applications Across Industry Verticals

The flexibility and standardized nature of Open Standard Modules make them attractive to a wide array of industry verticals. Essentially, any project that needs computing in a small, robust package can benefit from OSM. Here are a few notable application areas:

Industrial Automation and Robotics

OSM modules are ideal for industrial controllers and robots, where reliable, small-footprint computing is needed. They can act as the brains for autonomous mobile robots, robotic arms, or industrial HMIs – providing real-time control, machine vision processing, and on-device AI for tasks like object detection and navigation. The rugged, soldered OSM construction also tolerates high vibration, a crucial factor in factories and moving machinery.

Smart Cities and Infrastructure

Smart city deployments – from traffic monitors to environmental sensors – need compact, low-power, connected devices. OSM modules (especially with built-in wireless) fit this role by providing a standardized computing platform that can collect data (e.g. air quality or traffic flow) and send it over Wi-Fi or cellular networks. Their low-power operation even allows devices like parking sensors or streetlight controllers to run on solar power, all while maintaining a small physical footprint.

Healthcare and Medical Devices

Healthcare technology demands compact yet reliable computing for devices like portable diagnostics and patient monitors. OSM’s standardized modules can help meet strict medical requirements by using a proven compute core instead of a custom board. For example, an OSM module in a handheld vital-sign monitor can provide processing and wireless connectivity (Bluetooth to sync data to a phone, or Wi-Fi to upload records to the cloud) in a tiny form factor. The availability of multiple OSM vendors also gives medical device makers flexibility in sourcing and tailoring performance to their needs (with the specific processor platform that meets their compliance needs).

Consumer Electronics and Wearables

While OSM was designed for industrial use, it can also power consumer gadgets. For instance, a smart home hub could use an OSM module to run a Linux-based system that handles home automation protocols (Wi-Fi, Zigbee, etc.). The tiny form factor might even suit certain high-end wearables. And thanks to its plug-and-play nature, startups can prototype new devices with OSM modules on simple carrier boards, drastically cutting development time. In short, virtually any embedded application that needs a compact, reliable compute engine – from smart agriculture sensors to next-gen wearables – can consider OSM. The common thread across these use cases is the need for a balanced mix of performance, standardized I/O, and quick integration, all of which OSM provides. Notably, OSM was conceived for the IoT era, where computing must be embedded everywhere from door locks to farm sensors. By drastically shrinking module size and integrating wireless capabilities, OSM enables more intelligence at the network edge (closer to where data is generated) instead of relying solely on centralized processing.

The Future of Open Standard Modules

OSM is still a young standard (first released in 2020), but it is rapidly gaining traction. Multiple manufacturers have already delivered OSM-based products, and the ecosystem continues to expand with new processors and even spec refinements (v1.1 has already been released). With backing from major industry players like Avnet (a founding SGET member) and early adopters such as Advantech, OSM is likely to become a staple for IoT and edge computing designs in the coming years.

We can expect to see OSM modules adopting cutting-edge processors and catering to specialized needs – for example, variants optimized for AI acceleration or ultra-low-power operation – all within the flexible framework that the standard provides. This trajectory aligns with broader tech trends favoring open standards and modular design. Just as open standards in software and hardware have accelerated innovation, OSM’s open, multi-vendor approach fosters a collaborative hardware ecosystem. More adoption can drive more innovation and variety in modules, which in turn attracts even more users in a virtuous cycle.

For engineers and product developers, embracing OSM now means tapping into a platform poised for longevity and adaptability. Designs based on OSM have the ability to evolve — you can swap in next-generation modules to upgrade performance or add features without a complete redesign. That flexibility is crucial in the fast-moving IoT market. Open Standard Modules are an idea whose time has come, promising to unlock new possibilities for wireless embedded systems as technology and community support continue to grow.

For more on Ezurio’s line of OSM System-on-Modules, visit Ezurio CarbonAM62 and CarbonAM67 pages:

https://www.ezurio.com/system-on-module/osm-som/carbonam62-som

https://www.ezurio.com/system-on-module/osm-som/carbonam67-som

Courtesy of Ezurio