Tibbo Powers Cloud-Enabled Traceability Systems

Today, traceability is critical in all stages of the manufacturing process. Traceability allows manufacturers to follow the progress of their products throughout the entire production process, helping to identify problems. This is particularly important in the quality control (QC) phase — it is the last chance to ensure that products are safe, reliable, and meet specifications. This month, we’re sharing with you our approach to traceability.

Traceability generally requires the ability to identify each unit in production, typically with barcodes. These barcodes are scanned at each production step.

Tibbo’s cloud-enabled traceability solution consists of three components:

- WS1102 programmable serial controller with a barcode scanner

- TPS2L(G2) modular automation platform with an LCD screen

- A database and app in the Microsoft Azure cloud

The wireless nature of the WS1102 allows us to freely move them (and attached barcode scanners) between the workstations. A Tibbo BASIC app on the WS1102 receives and processes data from the barcode scanner and serves this data to our app in the Azure cloud.

At the heart of each workstation is a TPS controller. The modularity of the Tibbo Project System (TPS) means that we can tailor each unit to the needs of its station. One neat feature we’ve implemented is the configuration of WS1102 controllers via QR codes displayed on the TPS’ LCDs. This allows us to move the WS1102s and barcode scanners between the stations. Scan the code on the screen, and the WS1102 knows where it is.

Our Microsoft Azure app analyzes collected telemetry and keeps track of each step that a production unit has passed through. The system also records all additional test data generated at every step. The cloud-based system is crucial for identifying missed or improperly executed production steps.

Watch the video above for a demonstration of the whole system in action. For an even more detailed explanation, see our case study on traceability. Interested in implementing a similar traceability solution? Feel free to contact us for more information!

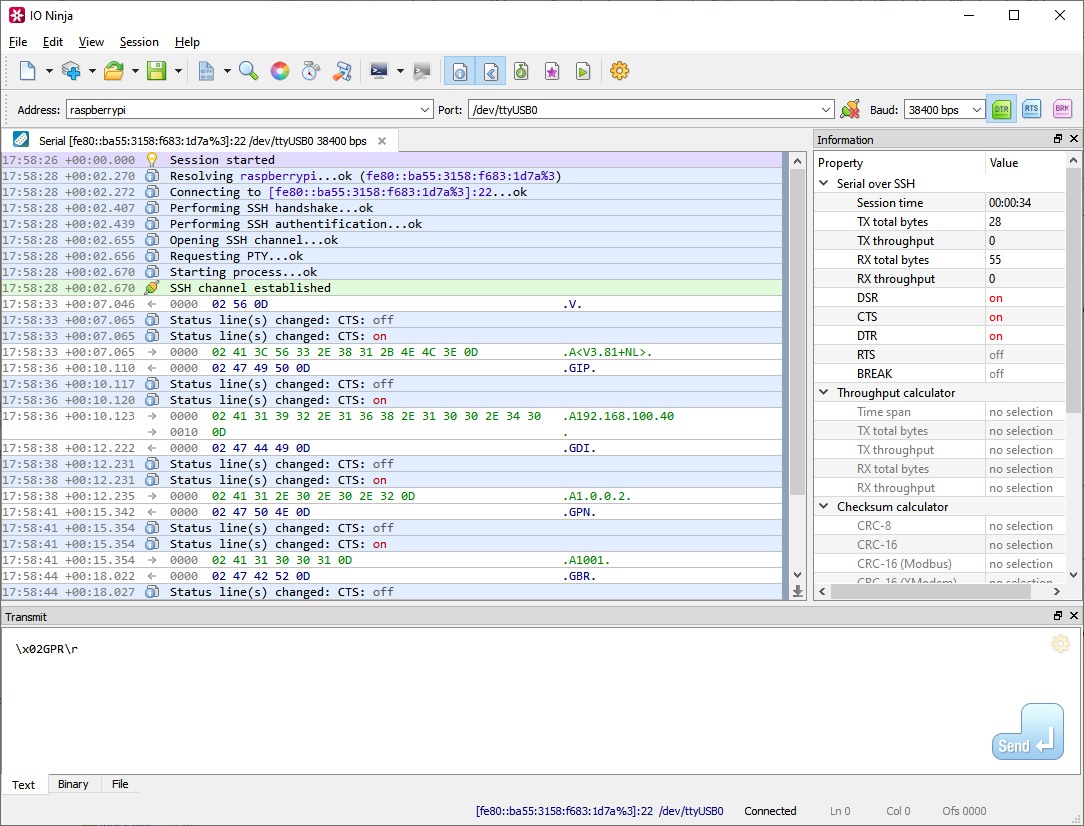

Control and Monitor Serial Devices Remotely With IO Ninja

The Serial plugin has always been one of IO Ninja’s most popular features. The world’s most advanced serial terminal supplies nearly every tool you would ever need when working via the serial interface. However, we feel that there’s always room for improvement, so with the release of IO Ninja 5.1.1, we took things one giant step further — we now offer Serial over SSH.

This highly requested feature enables you to control serial devices plugged into remote machines just as if they were connected directly to your PC. All the features of the Serial plugin you know and love are available for these remote connections.

This functionality is possible thanks to the IO Ninja Hardware Client, which was designed for deployment on headless Linux machines, such as Tibbo’s LTPP3(G2) or a Raspberry Pi. The combination of the Hardware Client and small, relatively inexpensive devices allows you to manage scores of serial devices remotely. The Hardware Client also enables the new Serial Tap over SSH and Ethernet Tap over SSH plugins, allowing remote access to your Serial and Ethernet Taps. This means you’re not limited to only serial connections, but can also remotely monitor serial and Ethernet traffic.

These three new plugins require the SSH capability, which is included in subscriptions or can be purchased individually.